7. Thinking about interaction

Something I have to start thinking about at this point is how will I interact with these screens. All the ones I purchased for experimenting have touch capabilities. Some are capacitive, some are resistive. Both have their differences, so should I go in that direction? On one hand they all already come with it, but then there's about 4-5 more connections I need to solder on each screen for touch, and from the tests I've done... it's a bit finicky.

But what exactly do I want to interact with and how? For starters if I'm going to build a device that supports multiple instruments, I need a way to selecting which one I want to display. Is touch really a good choice for something like this? And, if we look at the instruments in a typical cockpit, most of them have knobs and buttons.

Alternatives

- Touch:

- I'll be drawing a lot of stuff on tiny 3.2" screens, so I don't have a lot of room to add buttons. I played around with the idea of having the screen divided into 4 sections so I could use those as buttons, but for things like increasing/decreasing a heading bug on a Heading Indicator, a barometric pressure on an Altimeter, or an OBS on a VOR, it's unpractical.

- Pros:

- Already comes with the device

- Cons:

- Extra wiring

- Finicky and unpractical code

- Push Buttons

- I tried adding two buttons to each screen for going back and forth along the screens, but that was about it. I even 3D printed an oval shape cap for the 2 buttons that pretty much looked like the buttons on a DVD player for fwd/back that looked really good but I felt was only solving half of the problem.

- Pros:

- They are pretty straightforward to add and implement

- They are more reliable than touch on these type of devices

- Cons:

- Only solved half of the problem

- Rotary Encoders

- I messed around with the idea of a rotary encoder or two. Usually they come with an integrated push button so between two knobs and two buttons I would have more than enough inputs for the instruments I want to design

- Pros:

- With the rotary encoder, I could control different values that I could increment and decrement

- I also had available 2 buttons to assign to anything I needed

- Cons:

- There was really not a lot of room to put two rotary encoders on these small scale screens I'm designing, especially when everything is built and soldered by hand and with off shelf components.

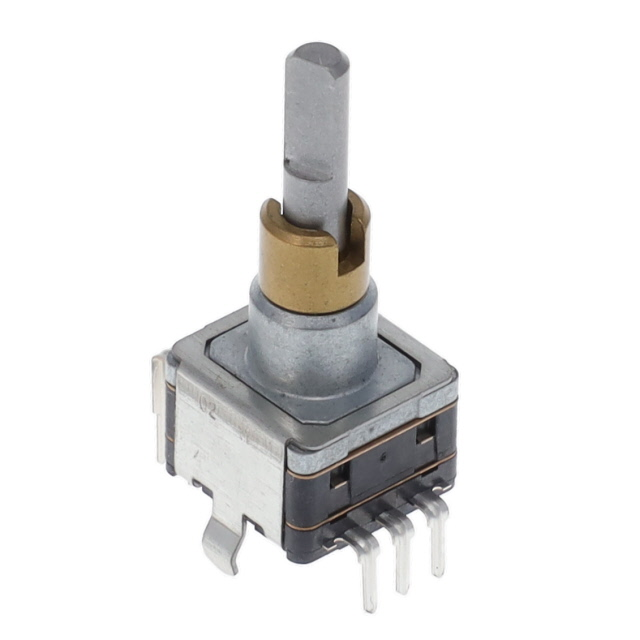

- Dual Rotary Encoder

- Pretty much the same as having two rotary encoders but in the space occupied by just one, but with the trade-off of only having one button instead of two.

- Pros:

- Same as two rotary encoders plus one is easier to mount and solder than two.

- Cons:

- They are a bit more expensive than regular rotary encoders

The Choice

After a lot of experimentation and testing, I decided to go with the dual rotary encoders. The extra cost is worth the simplicity and reduced space. I went with this one from Digikey and did not disappoint.